We had the pleasant opportunity to visit for 20 days, covering 2735 km of roads NEW ZEALAND and returned extremely surprised by the quality of roads in the country.

New Zealand has been successful in how to combine technologies way to get a paved road network of high quality. Let's start with comparative data with our country:

-New Zealand has 270,000 square km, 50% more than Uruguay.

-have 95,000 km of highways and roads (0.35 km / km2) of which 63,000 km are paved, 66% of the total.

-Uruguay 78,000 km road (0.44 km / km2) of which have 8000 pavings, only 10% of the total.

In other words, we have a higher density of roads per km2, but far we have long paved network as theirs.

It is that in New Zealand stabilization in situ with cement, lime or asphalt, is present decades, using as surface treatments surface layer and leaving only places high demands on the use of asphalt.

As we all know, the quality of the bases is essential, but if surface treatments are used as rolling. Conversing with them consulted engineers work, how they do it, and his answer was blunt: "It puts on a carpet and hard floor will last a lifetime, if you put on the clay have to throw very soon".

Transportation Agency's own New Zealand indicated on your website:

"The surface treatment is the most common type of rolling road in New Zealand. Economic, flexible and resilient, it provides an adaptable, safe and cost efficient surface for road users. We have a regular all surfaces to ensure they will perform at maximum follow.High traffic roads resealed usually need about every seven years, while roads that carry less traffic can last 15 to 20 years before resurfacing is required. " (Source:

NZ Transport Agency)

We share then as discussed with technicians work procedures used for construction of a typical road in New Zealand.

CONSTRUCTIVE PROCEDURE

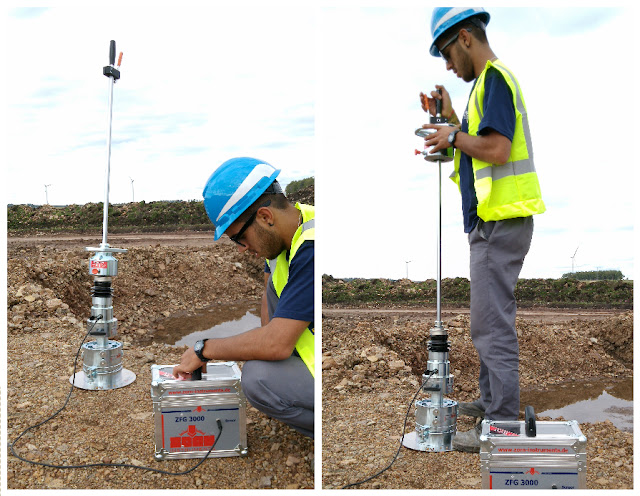

The kickoff is performing test base materials, the effects deeply know what material is counted. The development laboratory formulates a stabilization project based on cement, lime or asphalt and if you have enough good granular material in the area is considered the particle size stabilization with a maximum size of 65mm and the addition of 2% of cement.

The bases are treated perfectly with suitable materials, with the necessary granulometry compacted and cleaned before waterproofing.

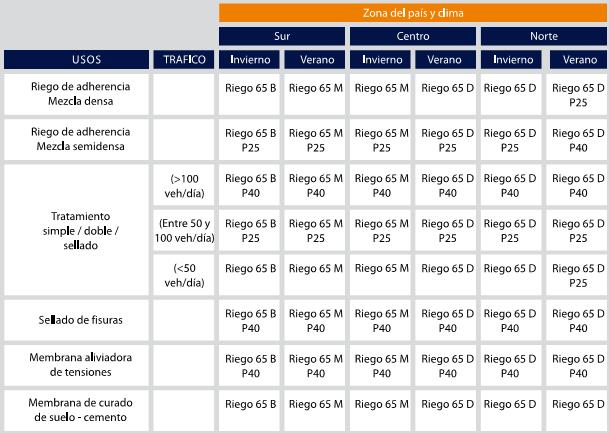

By having a very good base are limited to be as tread layer surface treatment with dry monogranular 6-12 mm and with the passage of time, when the treatment loses or shows a signal texture permeability, apply a second treatment with fraction 2-6 mm improving rolling and waterproofing structure again.

Then repeat the cycle with a large fine gravel 6/12 on and so on, always taking a road in perfect condition applying preventive maintenance at the optimum time.

Asphaltic used folders in the inner city, joints roads, highways exit of cities and in very short stretches of mountain roads when the slopes and angles are too demanding for a surface treatment.

The use of surface treatments monogranular or Chiping, reaches places such as a neighborhood of the city of Auckland, and most important port in the country and the North Island as seen in the photos below city.

Our trip was not only on this visit in the month of May

Bitafal group You will be participating in a

two-day course on technologies Chiping in the city of Christchurch in the South Island. In addition we already have a publication of more than 500 pages of the Manual on Chipsealing in New Zealand. Interesting document available on:

Chipsealing in New ZealandTo keep growing and researching, we have a long way to go.

We leave more photos in the following

link